Fast-moving retail shelves, complex warehouse systems, and expanding online orders are reshaping expectations for every label printer machine used today. Printing is no longer a background task; it directly affects order accuracy, inventory visibility, and customer satisfaction. A reliable label printer must now deliver speed, stability, and adaptability in equal measure. From our experience at Winpal, these evolving demands are driving new approaches to label printing across multiple industries.

Evolving Print Requirements Across Retail and Storage

Retail and warehousing environments demand consistent performance under pressure. High SKU volumes, frequent label changes, and long operating hours place heavy demands on equipment. A modern label printer must handle extended workloads without sacrificing clarity or alignment, especially for barcodes and product identification.

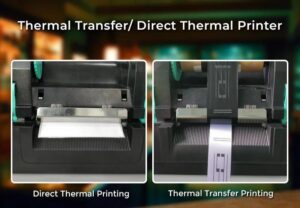

Transfer printing technology plays an important role here. By using ribbon-based printing, labels gain durability for long-term storage and transportation. This approach is especially valuable in warehouses where labels face friction, temperature changes, and prolonged handling throughout the supply chain.

Technology Advancements Driving Smarter Printing

Hardware innovation is shaping the future of the label printer machine. The WP300A 4 Inch Thermal Barcode Transfer Printer reflects this shift through its dual-motor gear-driven design, which improves paper feeding stability during high-speed output. With a printing speed of up to 127 mm per second, it supports fast-paced environments without frequent interruptions.

Processing capability also matters. A 200 MHz 32-bit RISC processor combined with onboard SDRAM and Flash memory enables smooth data handling, even in complex printing tasks. Long ribbon capacity, supporting up to 300 meters, reduces replacement frequency and keeps operations moving efficiently.

Adaptability for High-Volume and Automated Environments

Automation and self-service applications are becoming more common across retail and logistics. Kiosk-ready print mechanisms allow printers to integrate seamlessly into automated systems, reducing the need for manual operation. From our perspective at Winpal, adaptability ensures printing solutions remain useful as workflows evolve.

Scalability is equally important. Equipment that supports extended print runs, stable ribbon handling, and consistent output helps businesses expand without constantly upgrading hardware. A thoughtfully designed label printer machine supports both current demand and future operational growth.

Conclusion

The future of label printing is shaped by speed, durability, and intelligent design. As retail, warehousing, and e-commerce continue to evolve, choosing the right label printer becomes a strategic decision rather than a simple hardware purchase. At Winpal, we focus on developing printing solutions that align with real-world usage, helping businesses build efficient, resilient, and future-ready labeling systems.