Warehouse efficiency depends on how quickly and accurately shipping tasks are completed. Label printing sits at the center of this process, supporting order identification, tracking, and delivery coordination. In fast-moving fulfillment environments, a reliable 4 inch label printer helps teams manage large volumes of packages without frequent interruptions. Many warehouses now rely on a dependable thermal shipping label printer to ensure barcode clarity and smooth scanning throughout distribution channels.

Stable Printing Performance for High-Volume Warehouses

Continuous printing places significant demands on internal mechanics. A well-structured printer must maintain consistent paper feeding and alignment even during long production cycles. Compared with smaller formats, wider printers handle shipping labels more efficiently by allowing clear layouts and reducing data compression.

The WP-300B is designed with a double motor structure, providing stronger and more stable media movement. This design supports uninterrupted printing during peak shipping hours, helping warehouse teams maintain rhythm without frequent recalibration. In our experience, a properly engineered thermal shipping label printer contributes directly to smoother workflows by minimizing mechanical delays and print inconsistencies.

Flexible Media Handling for Complex Shipping Needs

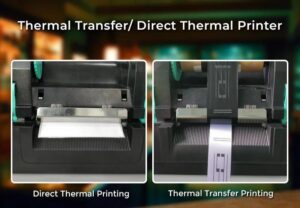

Warehouses often process different types of labels throughout the day, from standard shipping labels to specialized barcodes for sorting and storage. A capable 4 inch label printer must adapt easily to these variations without slowing down operations.

The WP-300B supports multiple media types, including continuous labels, gap labels, black mark labels, fan-fold labels, and punched-hole media. Multiple built-in sensors—such as gap sensors, black mark sensors, and positioning distance sensors—allow quick detection and accurate printing. External paper holders and label boxes further enhance adaptability, helping teams organize label supplies efficiently in high-volume shipping areas.

User-Oriented Design That Reduces Operational Downtime

Usability plays a major role in daily warehouse performance. Time lost to checking paper status or correcting loading errors adds up quickly during busy shifts. A transparent cover allows operators to monitor paper usage instantly, reducing unnecessary stops and manual checks.

From our perspective at Winpal, these design details matter just as much as printing speed. Clear visibility and easy access support smoother daily routines and reduce training time for new staff. When a thermal shipping label printer is intuitive to operate, warehouse teams can focus more on order accuracy and less on equipment handling.

Conclusion

Efficient warehouse operations rely on equipment that supports speed, flexibility, and consistency. A thoughtfully designed 4 inch label printer improves labeling accuracy while keeping shipping workflows organized and responsive. Through practical features, stable mechanics, and adaptable media support, solutions like the WP-300B help warehouses handle growing order demands with confidence. As a team at Winpal, we focus on creating printing tools that align with real operational challenges and support long-term warehouse efficiency.