Shipping efficiency often depends on how quickly and accurately labels are printed. From small parcels to bulk logistics orders, printer size directly influences workflow speed and label readability. Many businesses evaluating a 4 inch label printer are also comparing it with smaller formats to understand real performance differences. In shipping environments, choosing a reliable label printer for shipping can reduce errors and keep operations moving smoothly.

Printing Speed and Mechanical Design Across Label Sizes

Printer width affects not only label size but also mechanical stability. Smaller printers may handle light workloads, but wider formats are better suited for detailed shipping labels with barcodes and tracking information. A well-designed 4 inch label printer benefits from a stronger internal structure, especially during continuous printing.

Models like the WP-300B use a double motor design, providing more consistent paper feeding and reducing misalignment during high-volume tasks. From our experience, this mechanical strength supports smoother operation in shipping stations where labels are printed back-to-back. For businesses managing growing order volumes, a stable label printer for shipping helps maintain rhythm without frequent pauses or adjustments.

Media Compatibility and Connectivity in Shipping Workflows

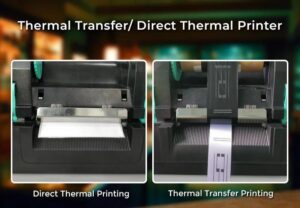

Shipping labels come in many formats, and printer flexibility plays a major role in efficiency. Different inch-size printers vary in how well they handle diverse media types. A capable 4 inch label printer should support continuous labels, gap labels, black mark labels, and fan-fold media without complex recalibration.

The WP-300B integrates multiple sensors, including gap, black mark, and positioning distance sensors, allowing quick adaptation to different label stocks. Support for external paper holders and label boxes further improves workflow organization. These features matter in real shipping environments, where a label printer for shipping must adapt to changing order requirements rather than slow them down.

Print Clarity and Usability for Daily Operations

Print quality remains a deciding factor, especially for barcodes that must scan accurately throughout delivery. Wider printers allow better spacing and layout, reducing barcode compression. A transparent cover, as used on the WP-300B, also improves usability by making paper status visible at a glance.

Ease of monitoring and loading reduces downtime during busy shifts. From our team’s perspective at Winpal, usability details often define whether a 4 inch label printer feels practical in daily operations or becomes a bottleneck. Clear output combined with simple handling strengthens confidence in a label printer for shipping across logistics workflows.

Conclusion

Comparing different label printer sizes reveals clear differences in speed, adaptability, and output consistency. A thoughtfully designed 4 inch label printer supports demanding shipping tasks through stable mechanics, broad media compatibility, and reliable print clarity. From our experience at Winpal, selecting the right printer size helps businesses build smoother shipping processes and maintain consistent performance as order volumes grow.