Market competition and brand identity are playing a larger role in how printing equipment is selected today. Businesses are no longer focused only on basic output; they are looking for devices that align with their visual identity and operational structure. This shift has pushed every thermal printer supplier to rethink how products are designed, produced, and delivered. At the same time, rapid development in thermal printer technology has made deeper customization possible without sacrificing production efficiency.

Customization Trends Driven by OEM and ODM Demand

OEM and ODM services have become essential for brands that want printing hardware to reflect their market positioning. Custom logos, unique casing designs, and branded packaging help businesses stand out in competitive environments. As a thermal printer supplier, supporting these needs requires flexible production processes and clear communication channels.

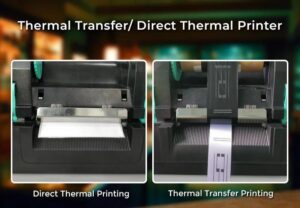

OEM services typically focus on brand identity elements such as stickers, silk printing, and customized packaging. ODM services go further by allowing full customization of appearance, software, hardware, and drivers. From our perspective, combining these services with advanced thermal printer technology helps partners create products that feel tailored rather than generic.

Advancements in Thermal Printing Technology and System Design

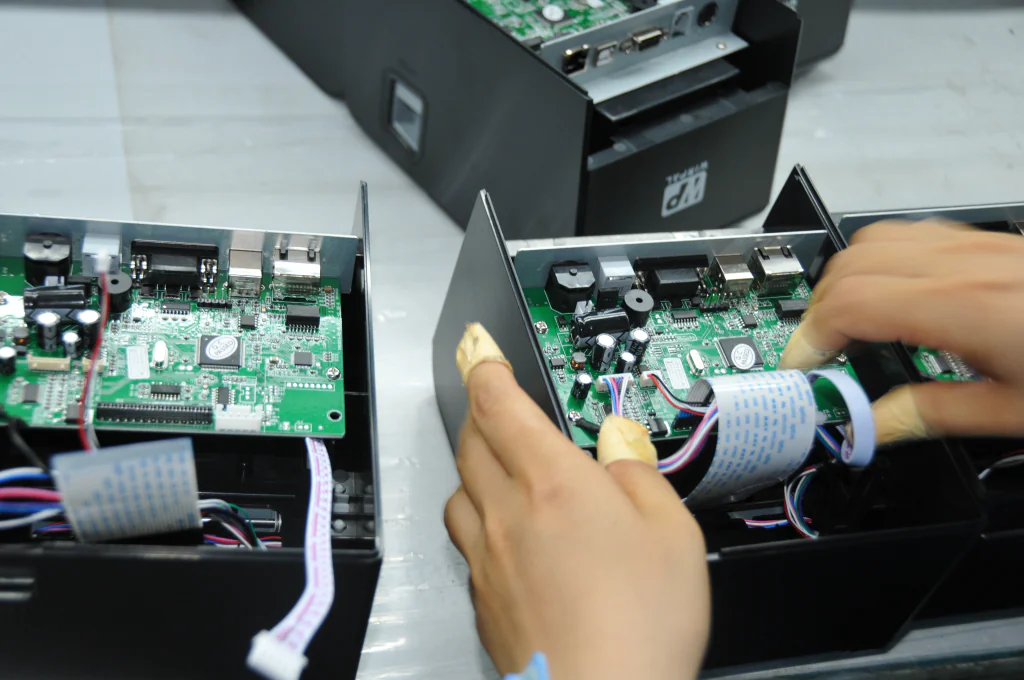

Modern thermal printer technology supports a higher level of adaptability than ever before. Software customization allows firmware and drivers to align with specific operating systems and usage scenarios. Hardware adjustments improve compatibility with different environments, while modular design shortens development cycles.

These innovations help reduce risk during customization. A capable thermal printer supplier must balance flexibility with stability, ensuring that customized products perform consistently after deployment. Our development approach emphasizes reliability throughout the customization process, allowing innovation to serve practical business needs rather than create complexity.

Efficient Collaboration Processes Behind Customized Printer Solutions

Successful customization depends on a structured collaboration workflow. The process usually begins with customers providing AI logo files and detailed requirements. Designers then determine suitable logo placement and confirm visual details before moving forward. Sample requirements are reviewed carefully to ensure expectations are aligned.

Development timelines typically range from 10 to 25 days, depending on the scope of customization. Clear checkpoints during this period help avoid misunderstandings and reduce revision cycles. From our team’s experience at Winpal, transparent collaboration allows thermal printer technology to be applied efficiently, helping customers bring branded products to market smoothly.

Conclusion

Innovation in printing hardware is no longer limited to performance improvements alone. Customization, process efficiency, and technical adaptability now define the value of modern solutions. Choosing a reliable thermal printer supplier means gaining access to structured OEM and ODM support backed by mature thermal printer technology. From our standpoint at Winpal, combining innovation with collaboration allows customized printing solutions to meet both branding goals and operational requirements with confidence.