In our experience as a thermal printer manufacturer, ensuring the longevity of a thermal printer is a key concern for businesses that rely on consistent, high-quality printing. At Winpal, we recognize that maintaining your devices properly not only preserves performance but also maximizes return on investment. By understanding proper usage and adopting routine maintenance, companies can achieve longer service life without compromising efficiency. Our solutions, such as the WP-F2 Direct Thermal Barcode Printer, are designed to support high-demand environments while facilitating easy care.

Optimal Paper and Media Usage

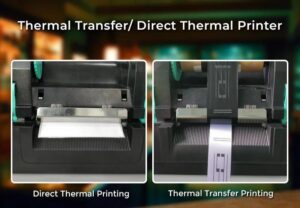

One of the essential factors in extending a printer’s lifespan is selecting the right printing media. Using appropriate thermal paper and avoiding incompatible substrates reduces wear on the printer head. With the WP-F2, which supports a space-saving design and a 32-bit processor, we emphasize compatibility with standard thermal media to prevent damage. By incorporating thermal printing technology thoughtfully, we ensure that our printers maintain high-quality output while reducing the likelihood of mechanical issues over time. This approach demonstrates our dedication as a thermal printer manufacturer to providing equipment that is durable and reliable.

Regular Maintenance and Firmware Updates

Routine maintenance plays a vital role in longevity. Cleaning the print head, checking the rollers, and keeping the internal components dust-free are all practices we recommend. Additionally, the WP-F2 supports ultra-fast print speeds of 152 mm/s and bi-colored status LEDs for quick printer status feedback, which facilitates regular inspections and proactive care. We also provide fast online firmware updates, ensuring that each device operates efficiently with the latest performance improvements. Leveraging thermal printing technology in this way helps prevent premature wear and enhances the printer’s overall lifespan.

Environment and Operational Practices

Operating conditions significantly influence printer longevity. At Winpal, we advise placing printers in stable, dust-free environments and avoiding extreme temperatures. Limiting continuous high-speed printing periods and allowing cooling intervals for the WP-F2 can prevent overheating. The printer’s rich emulation language compatibility—TSPL, ZPL, EPL, DPL—supports seamless integration into various workflows, which simplifies operations and reduces unnecessary strain on the device. Following these practices consistently demonstrates our commitment to delivering durable solutions as a trusted thermal printer manufacturer.

Conclusion

We understand that businesses depend on reliable printing for smooth operations, which is why we focus on both the design of our devices and the guidance we provide for their care. By using compatible media, conducting regular maintenance, and following operational best practices, companies can extend the life of their thermal printers. With models like the WP-F2, we combine thermal printing technology, rapid printing speeds, and robust build quality to ensure long-lasting performance. Choosing Winpal is choosing a partner that prioritizes device longevity and operational efficiency for every B2B client we serve.