As we support businesses across retail, logistics, and dining environments, we often explain how receipt equipment handles every print cycle in practical scenarios. At Winpal, providing clarity on the mechanism helps our partners choose suitable tools, especially when they compare different options offered by a receipt maker machine provider. Understanding the core operation also allows procurement teams and engineers to forecast performance, maintenance needs, and integration pathways with their existing systems.

Thermal Activation and Image Formation

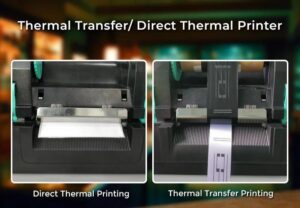

In many discussions with clients, we begin by outlining how heat-based printing forms characters and symbols. A thermal printhead contains fine heating elements that activate sections of heat-sensitive paper. As each element warms momentarily, the coated surface darkens, generating text, lines, or barcodes. This approach eliminates the requirement for ribbons or ink, which is a key reason businesses view a receipt maker machine as a practical choice for busy service environments. Our portable WP-T2C follows this principle, offering easy paper loading, ESC/POS compatibility, NVLOGO handling, and steady output suitable for ticketing and small-format receipts.

Motion Control and Data Handling

When explaining how a device processes incoming instructions, we highlight the connection between software commands and mechanical movement. A working unit receives data packets, interprets them through built-in firmware, and synchronizes each command with printhead activation. Simultaneously, a motor drives the paper through a platen so the heated elements mark the surface accurately. This coordination is essential for industries where operational efficiency affects customer flow. For those evaluating solutions from a receipt printer manufacturer, this structure demonstrates why thermal systems offer dependable and predictable results even during extended use. Many buyers also appreciate that a receipt maker machine maintains consistent clarity when producing small logos or one-dimensional barcodes, which is particularly relevant for retail and logistics workflows.

System Integration and Field Performance

As we assist clients deploying devices across multiple locations, we see how system compatibility influences purchasing decisions. Integration depends on stable communication protocols, support for common POS instructions, and the ability to sustain continuous printing without unexpected interruptions. Our company’s internal supply chain, complete management framework, and engineering experience enable us to refine these elements so each device aligns with business applications found in supermarkets, online commerce warehouses, food service counters, and healthcare facilities. In conversations with importers, wholesalers, and software vendors, we often discuss how a receipt maker machine maintains operational continuity when connected to diverse billing and ticketing systems.

Summary of Operational Value

By understanding how thermal reactions, motion systems, and firmware logic work together, users can better assess performance requirements for their daily operations. The mechanism reflects the standards we follow as a receipt printer manufacturer, guided by our production control, quality assurance processes, and customization capabilities. With practical design features and reliable construction, solutions like the WP-T2C support businesses that depend on clear, fast, and consistent printing across various environments. Through detailed explanations and steady product development, we continue assisting clients seeking functional and adaptable tools for receipt maker machine applications.