Thermal printing is a printing method used in many businesses today, but it does not work in just one way. There are two types of thermal printing methods: Direct Thermal (DT) and Thermal Transfer (TT). While both use heat to create images and text, they work differently and are suited for different needs.

This article will highlight the differences between direct thermal vs thermal transfer printers, so you can decide which option fits your business better.

Table of Contents

ToggleHow Each Method Works

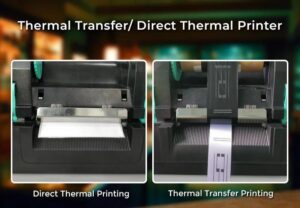

In direct thermal printing, the paper or label itself is heat-sensitive and turns black when it passes under the print head. No ribbon is needed.

Thermal transfer printing uses a ribbon placed between the print head and the material. The heat melts the ribbon’s ink, which then transfers onto the paper or label, creating the print.

Direct Thermal vs Thermal Transfer: Key Differences

To choose the right device, you must compare these two methods across several critical performance metrics:

1. Print Durability

Direct thermal printer outputs are inherently sensitive to environmental factors. Exposure to heat, bright sunlight (UV rays), moisture, or heavy friction will cause the label to fade or turn entirely black over time. Typically, DT labels are designed for a lifespan of less than six months.

Thermal transfer printer outputs, however, are built for the long haul. Since the ink is physically melted into the substrate, the print is resistant to heat, moisture, chemicals, and abrasion. These labels can last for years even in outdoor settings or industrial freezers.

2. Print Color

Direct thermal printing usually prints only in black because it depends on heat-sensitive material that darkens when heated. This limits its use to simple text or basic designs.

Thermal transfer printing can use color ribbons to produce prints in multiple colors. This allows for more detailed labels, logos, or designs. The ability to print in different colors makes TT printing more flexible for businesses that need colorful or branded labels.

3. Printer Lifespan

In direct thermal printing, the print head touches the heat-sensitive paper directly. The constant contact causes friction and wear, which can make the print head wear out faster.

In thermal transfer printing, the ribbon sits between the print head and the material. The ribbon acts like a shield, reducing wear on the print head. This is why TT printers usually have a longer lifespan and can handle more printing without problems.

4. Consumable Costs

Direct thermal printing only needs heat-sensitive paper or labels, keeping material costs low. Thermal transfer printing, however, requires both labels and thermal ribbons, which makes consumables more expensive.

5. Environmental Impact

Direct thermal printing uses only heat-sensitive paper, so it produces less waste and is generally more eco-friendly.

Thermal transfer printing, however, uses ribbons made partly from crude oil products, which increases its environmental impact.

6. Best Uses

A direct thermal printer will work well for receipts, shipping labels, pick slips, and other items that don’t need to last long.

A thermal transfer printer is better for product labels like library labels, compliance tags, and long-term warehouse or industrial applications.

Comparison Chart: At a Glance

Feature | Direct Thermal Printing | Thermal Transfer Printing |

How it Works | Uses heat-sensitive paper that darkens when heated | Uses a ribbon to transfer ink onto the material |

Print Durability | Can fade; affected by heat, sunlight, and moisture | Long-lasting; strong against heat, sunlight, and moisture |

Print Color | Usually black only | Multiple colors are possible with color ribbons |

Printer Lifespan | Print head wears faster due to direct contact | Ribbon protects print head; lasts longer |

Consumable Costs | Only paper or labels needed | Labels + ribbons; higher cost |

Environmental Impact | Less waste; more eco-friendly | Ribbons made partly from crude oil; less sustainable |

Best Uses | Receipts, shipping labels, short-term prints, etc. | Product labels, asset tracking, long-term or outdoor use, etc. |

Winpal’s WP300A Thermal Printer

At Winpal, we make thermal printers that help businesses get their printing done fast and efficiently.

Our WP300A Thermal Printer is a 4-inch thermal transfer/direct transfer printer built for busy work. It has a dual-motor gear system and prints at 127mm (5 inches) per second. The printer uses a 300-meter ribbon on a 25.4mm core and connects through USB 2.0.

It has a 200 MHz 32-bit processor with 8 MB SDRAM and 4 MB Flash memory, so it handles high printing tasks without trouble. This WP300A is great for printing product labels, shipping tags, barcodes, and for use in kiosks.

Conclusion

Choosing between direct thermal vs thermal transfer printers depends on what you need for your business. Direct thermal works well for short-term prints, while thermal transfer is better for durable labels. Check out our thermal printers and get yours today.